- Company

- Products

- Investor Relations

- Public Relations

- Sustainability

- R&D and QC

- Careers

- Customer Service

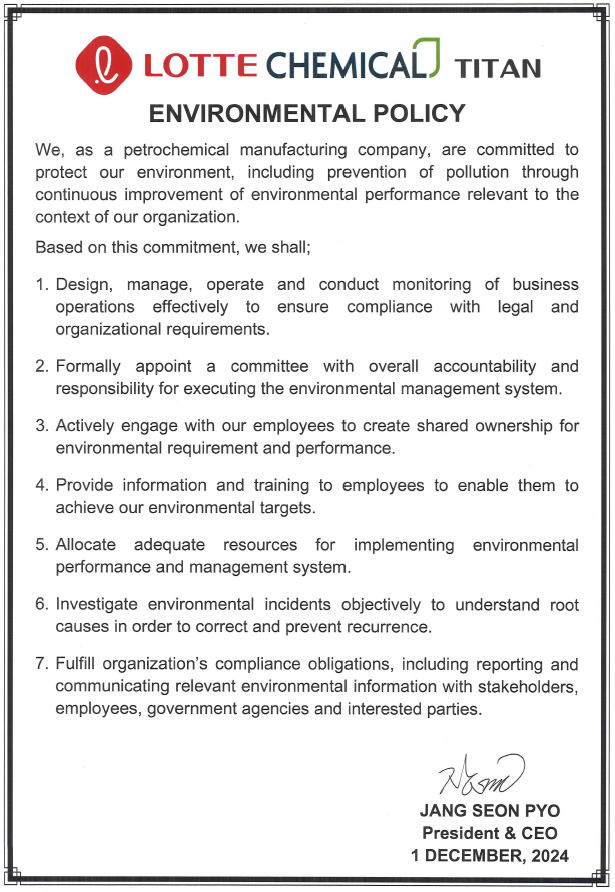

Environmental Management

Into the World, Into the FutureLOTTE Chemical Titan cares about the environment and continues to make our future and the globe greener.

Home

Sustainability

Environmental Management